Pumps

IMER PUMPS, MIXERS & DUMPERS

Leak Repair – Leak repair clamps

IMER is known world-wide for its mixers due to its vast experience from small, portable mixers to its large batch plants. No matter how large or small the project may be, IMER has a solution to help you maximize your time and ROI. Designed to handle the most impossible of mix designs and aggregate types. The IMER Multi-Mixers, Spin Series Continuous Mixers, and Vertical Shaft mixers are ideal for efficiently and quickly mixing all types of pre-blended materials from dry pack consistency to a fluid grout. Mortar one day, stucco the next. Tackle high-strength grouts the day after, or make them all in one day without any waste. In addition, IMER Mixers are designed to work with IMER mixer/pump spray machines and grout pumps – the perfect companions for semi-automatic production

MIX 360

THE MIX 360 OFFERS UNPARALLELED PRODUCTION AND JOBSITE / PLANT SAFETY

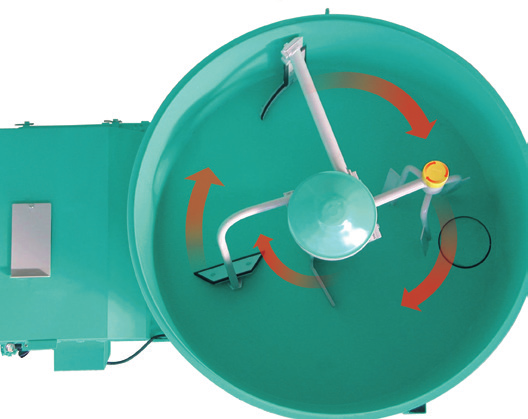

Vertical shaft mixers use the principles of concrete batch plant design, which allows for the paddles to rotate

through the mix rather than lift and drop it as conventional mortar mixers do. The Mix 360 vertical shaft towable

mixer easily mixes very low slump materials like dry pack mortar and refractory cement, as well as UHPC.

| Parameter | Specification | Unit / Remarks |

|---|---|---|

| Drum Capacity | 12 | cu ft |

| Batch Output* | 9 | cu ft |

| Drum Diameter | 38 | in |

| Maximum Aggregate Size | 3–8 | in |

| Discharge Outlet Height | 30 / 18 | in (Max / Min) |

| Pneumatic Wheels | 18 | in |

| Weight (Electric / Gas) | 787 / 794 | lbs |

| Electric Motor Rating | 5 hp | 220V, 1ø or 3ø |

| Gas Engine* | 11 hp | Honda |

| Width*** | 44 (50) | in |

| Length*** | 59 (80) | in |

| Height*** | 58 (56) | in |

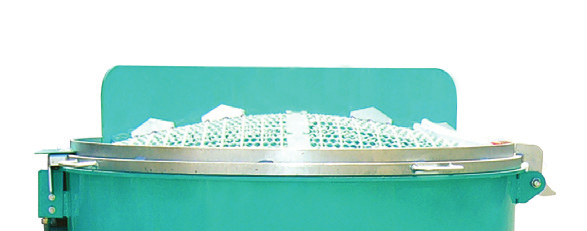

OPTIONAL DUST GRATE

ACCESSORIES FOR SAFETY

PRODUCTION

INDUSTRIAL ELECTRIC MOTOR

MIX 750

PRODUCE 18 CUBIC FEET OF MUD EVERY THREE TO FOUR MINUTES WITH THE MIX 750

The Mix 750 is the perfect partner for busy precast mixing operations, and on bridge and highway jobs. The discharge system is easy to open and

close and protected from being hit by a mud bucket or forklift. The safety grate is hinged, making access immediate. The Mix 750 is Mini-Batch

Plant production for a fraction of the cost. These mixers develop vast amounts of mixing power, far more than any horizontal shaft mortar mixer.

The ability to mix refractory mud or stiff, dry materials is unparalleled in the industry

| Parameter | Specification | Unit / Remarks |

|---|---|---|

| Drum Capacity | 22 | cu ft |

| Batch Output* | 15 | cu ft |

| Drum Diameter | 52 | in |

| Maximum Aggregate Size | 3/8 | in |

| Discharge Outlet Height | 29 / 23 | in (Max / Min) |

| Pneumatic Wheels | 22 | in |

| Weight (Electric / Gas) | 1588 | lbs |

| Electric Motor Rating | 5 hp / 7.5 hp | 220V 1ø / 220V 3ø |

| Gas Engine* | 13 hp | Honda |

| Width*** | 63 (64) | in |

| Length*** | 90 (86) | in |

| Height*** | 62 (64) | in |

KOINE 4

A POWERFUL, VERSATILE CONTINUOUS PUMP

| Parameter | Specification | Unit / Remarks |

|---|---|---|

| Power Supply | 220V / 60Hz | 3 Phase |

| Total Machine Power | 9 | hp |

| Drive Motor Power | 7.5 | hp |

| Feeding Impeller Motor | 1 | hp |

| Water Booster Pump | 1 hp | 70 psi boost |

| Material Flow Rate | 140 | cu ft / h |

| Max Pumping Distance (Grouting / Fireproofing*) | 200+ | ft |

| Max Pumping Distance (Self-Leveling*) | 300+ | ft |

| Gearbox Speed | 400 | rpm |

| Loading Height | 35½ | in |

| Dimensions | 29 W × 47 L × 61½ H | in |

| Weight | 574 | lbs |

DUST GRATE INCLUDED

Take control of dust. Easily attach IMER’s iDUST® dust grate and attach a vacuum, watch the dust pull downward, away from operators.